We know how crucial reliable communication is for railroads and the other industries we serve. We also know that finding large, high-quality dishes for railroad communications has been a challenge with limited options in the market.

That’s why we’re thrilled to announce that we are now an official distributor for Alive Telecom brands, including Alive Telecom, RadioWaves, and KP Antenna!

This partnership allows our customers to access superior, U.S.-made antenna solutions with shorter lead times, ultimately increasing efficiency, reducing downtime, and improving overall communication performance.

But it’s not just about railroads! This expanded product line benefits other industries looking for high-quality, reliable antenna solutions. With Alive Telecom brands, we’re ready to bring you the best in communications technology!

Ready to learn more? Reach out to Andrew at andrew@castlerockmicrowave.com to discuss how this new partnership can affect your communication solutions.

We had a great time welcoming industry leaders and partners to our 2nd Annual Tech Lunch last month!

Wes Wright and Tim Doughty of Keller and Heckman gave an outstanding Q&A for our guests on topics including tower compliance requirements, enforcement trends, 4.9 GHz deployments, and 6 GHz link monitoring.

Dale Bass of PCTEL gave a real-time demo of their interference management services.

Thanks to everyone who made this event a huge success!

Meet Fred Corsentino, one of our trusted advisors!

Fred’s leadership in driving growth and his deep understanding of the telecom industry make him an invaluable addition to our team. His expertise aligns perfectly with our mission to deliver top-tier communication solutions, and we are confident that his guidance will help us continue to innovate and exceed our clients’ expectations.

Thank you, Fred!

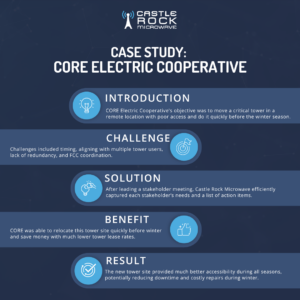

CORE Electric Cooperative needed to quickly move a critical tower in a remote, hard-to-access location before winter.

With limited resources to pull off this complex move, CORE turned to Castle Rock Microwave to manage the project and handle the microwave portion of the project.

CORE was able to achieve:

Whether you're experiencing networking issues, wondering how to maximize your return on technology investments, or have a question about growing leased-line circuit costs, reach out anytime.

Last month we hosted an engaging event focused on protecting Operational Technology (OT) networks from cybersecurity threats.

A big thank you to our expert speakers—Vince Varga (Castle Rock Microwave), Jeremy Dreyer (SkyHelm), and Jason Edgcomb (BeyondTrust)—for delivering such an informative session. Thank you to all who joined us!

Stay tuned for more educational opportunities and industry insights.

We're excited to have Rick Dunn advising Castle Rock Microwave on leadership development. Rick holds a Ph.D. in education and brings invaluable expertise to our team with over thirty-five years of experience as a coach, mentor, pastor, and non-profit leader.

Rick’s mission to "inspire, empower, and equip spiritual leadership for the 21st century" helps us foster a culture of growth and innovation. His guidance helps us serve you with excellence.

Welcome, Rick! We look forward to the positive impact your leadership development expertise will have on our organization and customers!

Like many districts, the Douglas County School District (DCSD) faced challenges managing a complex communications infrastructure across multiple buildings.

They partnered with Castle Rock Microwave to streamline their network operations and increase efficiency to help keep students, teachers, and school personnel safe and connected.

Our comprehensive solution meant that all buildings achieved connectivity across their respective campuses, giving first responders the coverage to communicate properly.

Check below for the full story!

The Trusted Partner Network connects industry leaders to collaborate on advanced microwave and secure outdoor wireless projects, leveraging shared expertise and resources for innovation and mutual success.

We've invited select participants to join this initiative to help us continue to serve our customers better.

Why do people choose to participate in the TPN?

Reach out to Natalie at natalie@castlerockmicrowave.com to learn more about joining the Trusted Partner Network.

Whether you're experiencing networking issues, wondering how to maximize your return on technology investments, or have a question about growing leased-line circuit costs, reach out anytime.

Have you saved your spot for next week’s complimentary industry lunch & learn on Tuesday, July 30?

Explore how you can best protect your OT network, hear expert insights, and get answers to safeguarding OT network questions in real-time while networking with your peers.

Lunch will be provided & in-person spots are limited.

Discussion topics include:

Location: In-person at Castle Rock Microwave, 520 Topeka Way, Unit 2, Castle Rock, Colorado. A virtual meeting link will be provided to those who cannot attend in person.

*This event is intended for end-users only (rather than manufacturers or suppliers).

"We guarantee your system will work as designed for the first year, or we'll make it right."

You need a reliable network that gives you security and peace of mind. We understand the frustration of system failures and their impact on your business operations - that's why we stand behind our professional services.

The Castle Rock Microwave Guarantee means that you can trust your system will work as designed for the first year, or we'll make it right.

This means fewer disruptions, less downtime, and more focus on what truly matters—keeping your critical systems running!

Many cities face challenges as they future-proof their networks, preparing for smarter tech and real-time monitoring that can stress existing networks.

The City of Pueblo was facing this challenge when they partnered with Castle Rock Microwave. In our latest case study, you'll see how our solutions resulted in reduced downtime, improved operational productivity, and significant cost savings.

The case study also highlights that by establishing the Internet of Things backbone, the city positioned itself ahead of anticipated challenges, such as implementing a real-time crime center.

Read the full story here.

Whether you're experiencing networking issues, wondering how to maximize your return on technology investments, or have a question about growing leased-line circuit costs, reach out anytime.

You’re invited to our complimentary industry lunch & learn. Get expert insights into how to protect your OT network while you network with your peers.

Lunch will be provided & in-person spots are limited.

Discussion topics include:

Location: In-person at The Lab at Castle Rock Microwave, 520 Topeka Way, Unit 2, Castle Rock, Colorado. A virtual meeting link will be provided to those who cannot attend in person.

How is your railroad using the 900 A Block spectrum? Did you know this resource is available to you and if you don’t use it, you lose it?

900 A Block can help enhance your channel coordination, keep your network compliant, and protect against unprotected spectrum.

Schedule a consultation to better understand your options. Reach out to us below to get started.

We're always looking for strategic partnerships to better serve you, our customers, and our partners.

We are proud to announce Steve Bay, owner of Aero Constructors, has joined our team as Head of Operations.

Steve brings unparalleled experience to Castle Rock Microwave, including two decades of tower company ownership and three decades of experience as a microwave technician.

Steve is also a:

Steve's partnership is part of our strategic growth plan as we strive to set the standard for excellence.

We are excited to have him, his experience, and all that Aero Constructors brings as we work together to serve our customers! Say hi to Steve on LinkedIn!

How do you deal with network interference as a public safety official? Lifesaving public safety infrastructure must be reliable – which means you need to protect your radio coverage area and keep it performing.

Did you know the below resources are available to public safety officials?

If you're interested in these resources, a demo, or a trial for your radio network, just let us know!

Whether you're experiencing networking issues, wondering how to maximize your return on technology investments, or have a question about growing leased-line circuit costs, reach out anytime.

Prevent costly downtime, enhance network efficiency, and discover robust connectivity tailored to your specific needs with an expert site audit.

You need a custom plan to reduce interference and provide a reliable connection for non-outdoor wireless solutions - based on your network, building environment, and resources.

Contact us today to schedule your complimentary site/ground audit (grounding, UPS), DAS/BDA, power, and custom-kitted cabinet and enclosure solutions.

This innovative system will play a pivotal role in supporting the county's P25 Public Safety Radio Network and provide robust local coverage of the state's interoperable Digital Trunked Radio System.

Rio Blanco County needed to expand and optimize its broadband network to provide reliable connectivity in rural areas - and we were more than happy to help! To achieve their goal, we installed microwave and fiber equipment to enhance infrastructure and extend service reach to underserved communities.

The project resulted in significant cost savings and was completed ahead of schedule.

It was great to see everyone at the In-Building Public Safety Communications Seminar hosted by the Safer Buildings Coalition!

If you didn’t get a chance to stop by our table - you can grab the resource we were offering here - a complimentary ERCES plan submittal template.

From there, our team headed to the 2024 Radio Summit hosted by the Public Safety Communications Subcommittee, where we presented “Four Insights to Improve Controls for Radio System Stakeholders."

Check out this article from RCR Wireless, covering that the FCC has requested additional funding to support the "rip-and-replace" initiative, which aims to remove certain equipment from U.S. networks due to national security concerns.

Without this funding, many rural telecom providers may face shutdowns, risking the loss of essential communication services in remote areas.

Whether you're experiencing networking issues, wondering how to maximize your return on technology investments, or have a question about growing leased-line circuit costs, reach out anytime.

The Castle Rock Microwave team is proud to support the Safer Buildings Coalition! Join us at their upcoming interactive seminar based on model codes for in-building public safety communications systems.

Stop by our table and say hello to Vince to grab your copy of our complimentary template: Pre-ERCES coverage survey checklist and ERCES plan submittal.

Thursday, May 9, 2024

9:00 am - 2:30 pm

Did you know? Radio equipment is not set-it-and-forget-it. Manufacturers go out of business, and certain radios and equipment become obsolete - meaning your network can have components that aren’t working as they should.

Unfortunately, this can lead to downtime, service disruptions, security issues, and lost revenue.

If you’re wondering about your equipment and the impacts to your network, we’re currently offering complimentary point-to-point link analysis & budgetary pricing for microwave link upgrades.

Reach out below to schedule time with a specialist.

Through discovery, design, deployment, and support, our 3DS™ process sets your network up for today - and tomorrow.

It all starts with discovery, where we execute the following to test your network’s real-world viability.

Discovery is the foundation of our process and sets the stage for your future-proof network.

Spectrum allocation directly impacts your access to wireless connectivity and emerging technologies like 5G. Efficient spectrum usage enhances telecommunications infrastructure and fosters innovation and economic competitiveness.

The National Spectrum Strategy Implementation Plan outlines essential timelines for spectrum band studies, critical for addressing the rising demand for wireless connectivity and advancing technologies like 5G.

Whether you're experiencing networking issues, wondering how to maximize your return on technology investments, or have a question about growing leased-line circuit costs, reach out anytime.

In the latest 5G Guys podcast episode, hosts Dan McVaugh and Wayne Smith interview Jeff Vaughn with Douglas County Sheriff’s Office and our very own Cody Martin on the important topic of public safety communication in schools.

They share common pitfalls as well as unexpected impact, and provide an overview of the work done by Castle Rock Microwave to enhance in-building communication.

From infrastructure to security, get 24/7 monitoring of your systems to ensure that when outages or issues occur, you’ll be able to react quickly with expert support.

Get in touch with a member of our team to learn about Lifecycles Services and how the service can support your organization’s communication network.

With Lifecycle Services, you can:

When you trust us to keep an eye on your systems with Lifecycle Services - we aim to find issues before you do.

Want to learn more? Reach out here.

Whether you're experiencing networking issues, wondering how to maximize your return on technology investments, or have a question about growing leased-line circuit costs, reach out anytime.

The City of Aurora is a Home Rule Municipality located in Arapahoe, Adams, and Douglas counties, Colorado. Aurora lies immediately east of Denver. It is one of the principal cities of the Denver–Aurora–Lakewood, CO Metropolitan Statistical Area and a major city of the Front Range Urban Corridor.

The City trusts Castle Rock Microwave to help them overcome their wireless connectivity challenges. As a result, they turned to CRM when they were looking to upgrade connectivity at several community locations in late 2020.

Castle Rock Microwave suggested wireless solutions from Cambium Networks in 60 and 80GHz. These millimeter wave frequencies are ideal for achieving fiber-like speeds at a fraction of the cost of building new fiber infrastructure.

We recommended the PTP850E for 80GHz and cnWave v5000 and v3000 for 60GHz. The PTP850E is an ultrahigh capacity, all-outdoor backhaul that delivers up to 20 Gbps capacity. The cnWave uses Terragraph, Facebook’s new terrestrial connectivity technology.

PTP850E

cnWave v5000

cnWave v3000

Terragraph opens up a new way to use the large amounts of unlicensed spectrum available in the 60 GHz millimeter Wave band, using a mesh architecture that can be used for many FWA, backhaul, smart cities and IoT use cases. With the increase in demand for gigabit connectivity and the availability of commercial equipment, Terragraph has become a hot technology, with the first large commercial deployments expected in 2021.

To find out more about Terragraph and the opportunities it offers to service providers, cities and enterprises, register here to receive the report that will be available soon, or download the interviews that will be part of the report as they become available.

Photo by Vlada Karpovich on Pexels.com

In 2020, rural telcos that provide wireless internet access have seen many rapidly developing events that have impacted their businesses. Instantaneous increases in demand due to COVID, RDOF applications, CBRS Auction and CARES Act money/grants have been pushing rural telcos to optimize network performance and capacity. In this article, I will address some of the performance issues rural telcos with broadband services are seeing and solutions to optimize wireless networks.

This increased demand has left many providers struggling to keep up to their overtaxed networks. In addition, they are having problems providing reliable service and their customers are starting to look for better alternatives.

In a recent article , Mike Dano states, “As office workers, students and others continue to seek shelter at home from COVID-19, demand for speedy and reliable Internet service appears to be at an all-time high. That demand is beginning to have serious effects on the nation’s telecommunications providers.” “Capgemini recently surveyed 6,300 US consumers and found that almost half (48%) felt their Internet connections didn’t meet their needs. The firm also found that customers are increasingly looking at their connection’s flexibility and network speeds, rather than just the reliability and price.”

With so much expansion occurring within internal networks and competitors’ networks, interference can slowly creep in degrading performance.

New users and greater capacity demands are now exposing issues with bandwidth management. Furthermore, poor bandwidth management from inefficient design practices decreases available bandwidth and decrease capacity in the distribution network.

There are solutions, but there are often tradeoffs as well. The decisions on performance are being driven by market demand and existing capacity. With rapid expansion of user expansion and bandwidth demand, your wireless access points and network can quickly become overburdened. Start with an audit of RF performance by an RF expert to see which problems you are experiencing.

One solution is using more directional antennas at access points. This will help performance by:

Another solution is using smaller cells or micro PoPs. This can increase capacity, improving the user experience. Each access point is limited the least common denominator of capacity its users are receiving. As a result, wide ranges of distances from the access points can play havoc on performance. Therefore, tighter variances and shorter distances will help set customer expectations.

Adding capacity is an obvious solution. 25/3 is no longer the real standard, users are now demanding 100’s of Megs or even Gigabit capacity. There is a new disruptive carrier class PTP option pushing multiple gigabits per second. And it is one of the most cost-effective solutions in terms of cost per megabit per second per mile. This product provides the highest capacity in a single transceiver radio with 2.5Gbps (single radio – 2x112MHz channels) or 1.5Gbps (single radio – 2x80MHx channels) at 4096 QAM. For more information on implementing this system, please visit our Case Study with South Park Telephone Company.

For the distribution network, implementing massive Multi-User MIMO or MU MIMO solutions will provide greater access to users and capacity. Many carriers are using less robust, standard MIMO solutions and are reaching user density thresholds. Accordingly, they need a technology leap to support more users at higher capacity. Cambium’s PMP450m (cnMedusa) is a high-capacity multi-point solution that can provide more than 400 Mbps actual usable throughput per sector, and communicate with up to seven Subscriber Modules simultaneously. With 8×8 MU MIMO it provides 4x more spectrum efficiency than any other vendor. It also impressive Near or Non-LOS capabilities as well for more flexible installations.

Purchasing microwave equipment is a long-term decision with implications on future needs, sustainability, and total cost of ownership. A few years ago, Brett Bonomo wrote an article on this topic that covers key questions to ask including:

For more detail visit the complete article at https://castlerockmicrowave.com/selecting-the-right-radio

Would you feel more comfortable hearing from others when evaluating technology? Great, there is a great Facebook page that hosts over 10,000 members where you will likely find answers to your many questions from companies much like yours.

CBRS (Citizens Broadband Radio Systems) is now being considered by many telcos for a last mile solution. If you are not familiar with this newly available spectrum (3550-3650MHz), here is a quick article on CBRS

What are some of the key advantages of CBRS?

With fewer issues of interference and more flexible antenna locations this means happier customers and fewer truck rolls to tweak your network.

Companies operating CBRS networks need to employ someone with a CPI, either directly or via consultancy. There are many online training courses to get certified. Make sure the training course registers you in the WinnForum CPI database and send your credentials automatically.

Castle Rock Microwave can assist you with a coverage comparison analysis or try it yourself if you are familiar with LINKPlanner (Cambium Networks) or Pathloss software.

Castle Rock Microwave is a turnkey, regional system integrator for microwave backhaul, fixed wireless broadband and WI-FI solutions for Rural Telcos, Utility Companies and Public Safety agencies. We view your wireless system as an integral part of your operation and create holistic RF designs with your entire systems, sustainability, and future business goals in mind. We are vendor agnostic and work with our clients in choosing the best solution for performance, maintainability, and budget in mind. Call us for:

Current market conditions are creating opportunities for rural telcos to expand their users and networks and in some cases with substantial grants. Wise long-term investments in the correct gear will separate the leaders from the competition. Make sure your designs are considering all the factors when deploying or optimizing your wireless network and contact Castle Rock Microwave for help at sales@castlerockmicrowave.com or call 303-358-7039.

The last several months have had a significant impact on Public Safety agencies. Budgets for the next few years have been cut drastically as sales tax revenues drop and the impact the Gallagher Act reduces incoming revenue. To date, the vote on the Gallagher Act has not been decided. Now, municipalities are becoming more conservative in spending. In some cases, they are asking to extend the lifespan of radio networks. Additionally, they are still expecting the same reliability of critical communications. One way to do that is through microwave radio maintenance contracts and lifecycle planning. Are you concerned about having to do more with less?

Microwave systems are often installed and are out-of-sight, out-of-mind. However, if left alone, your fixed microwave systems will eventually degrade in performance and be susceptible to cyber security breaches.

Exposed to wind, sun, hail, snow and rain over time, antennas, cables, and radios slowly degrade in performance. Furthermore, gradual degradation is difficult to recognize until there is a complete failure. Here are some of the typical problems that occur at microwave sites if not installed properly:

Castle Rock Microwave’s Lifecycle Services are a comprehensive approach which safeguard, improve performance, and extend the lifespan of your mission critical wireless systems. Reliability and total cost of ownership are key factors when operating a mission critical network. And Lifecycle Plans are key to operating a cost-efficient system. Lifecyle Plans normally include:

Here is a Case Study of how Douglas County Sheriff’s Office deployed a Network Management System to monitor their communication network, respond to issues before they became critical and simplify three monitoring systems into one.

Castle Rock Microwave works with public safety agencies in deploying microwave system and extending their lifespan through Lifecycle Services. Please contact Castle Rock Microwave for a free consultation at sales@castlerockmicrowave.com or 303 358-7039 for help in these areas.

"We guarantee your system will work as designed for the first year, or we'll make it right."

Please CLICK HERE to read our full Terms & Conditions